Salt Soda Ash Dispensing System

200000.00 - 500000.00 INR/Unit

Product Details:

- Drying Method N/A (Dispensing System)

- Weight Approx. 750 kg

- Pressure Range 0.1 to 0.5 MPa

- Condition New

- Drive Type Automatic motor-driven

- Machine Type Salt Soda Ash Dispensing System

- Working Width Customizable as per requirement

- Click to View more

X

Salt Soda Ash Dispensing System Price And Quantity

- 200000.00 - 500000.00 INR/Unit

- 1 Unit

Salt Soda Ash Dispensing System Product Specifications

- Ambient to 40C

- Below 70 dB

- Automatic motor-driven

- Customizable as per requirement

- Salt Soda Ash Dispensing System

- New

- 0.1 to 0.5 MPa

- N/A (Dispensing System)

- Approx. 750 kg

- Electric

- Up to 500 kg/hr

- PLC based digital control panel

- High precision dispensing, corrosion-resistant body, dust-free operation, low maintenance

- Variable, controlled through panel

- 415V AC, 3 Phase, 50 Hz

- Salt, Soda Ash, and similar powders

- As per client specification (typically 2000*800*1800 mm)

- 2024

- Fully-automatic Dispensing Unit

Salt Soda Ash Dispensing System Trade Information

- 10 Unit Per Month

- 2-12 Week

Product Description

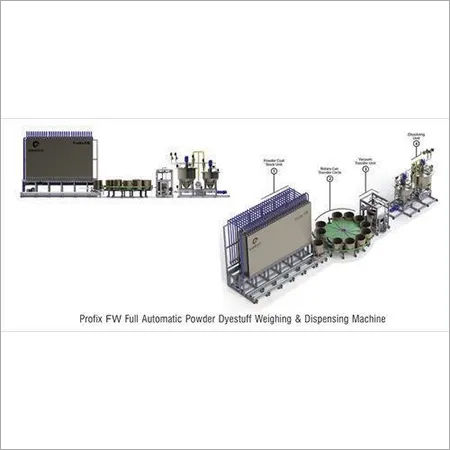

Profix S is a Salt, Soda Ash Dispensing System. Profix S is a high precision fully automatic system that can send the desired amount of chemicals to your machines in a desired amount in time & to the desired point.

Features:

- Liquid Chemical Dosing

- User friendly Touch Screen

- Easy Assembling

- Valve leakage test system

- Works simultaneously with Simplex control device & software

- Single Line Dispensing System

- Minimum service & maintenance due to special design

- Minimize costs while minimizing operator errors

- Details reporting

- Remote connection & software update

- Report & Analysis Software

Advanced Dispensing Mechanism

Equipped with a PLC-controlled screw conveyor and an innovative anti-bridging design, the Salt Soda Ash Dispensing System ensures precise, continuous feeding. Its digital LCD indicators allow real-time monitoring and adjustment of operational parameters, minimizing errors and maximizing throughput. Thanks to these intelligent mechanisms, materials are delivered efficiently and reliably, even in demanding industrial environments.

Robust Construction for Longevity

This dispensing system features a body built from powder-coated mild steel or optional SS 304 for enhanced corrosion resistance. Each unit is engineered for durability and operates reliably in ambient temperatures up to 40C, supporting a service life exceeding 10 years under expected load cycles. A standard wooden crate or custom packing ensures safe transportation and easy installation at your facility.

Operator Safety and Ease of Use

Safety is paramount with built-in emergency stop, overload protection, and system interlocks. The automatic operation, noise level below 70 dB, and dust-free dispensing environment create a user-friendly workspace. Comprehensive on-site installation assistance and low maintenance requirements further ensure the systems smooth integration into new or existing production lines.

FAQs of Salt Soda Ash Dispensing System:

Q: How does the Salt Soda Ash Dispensing System maintain high discharge accuracy?

A: The system utilizes a PLC-based digital control panel and a screw conveyor with an anti-bridging design, providing precise control over the dispensing rate. This technology delivers a discharge accuracy of 1%, ensuring consistent and reliable dosing for your industrial processes.Q: What types of materials can be dispensed using this system?

A: The Salt Soda Ash Dispensing System is specifically engineered to handle salt, soda ash, and similar powdered substances commonly used in textile, dyeing, and chemical process plants. Its robust construction and anti-bridging screw conveyor guarantee uninterrupted performance with a variety of powders.Q: When is on-site installation assistance available for this system?

A: On-site installation assistance is provided upon purchasing the system. Our team coordinates with you to schedule installation at a convenient time, ensuring correct setup, system calibration, and training for smooth operation from the start.Q: Where can the dispensing system be installed?

A: The systems dimensions and design can be customized as per client specifications, allowing installation in textile mills, dyeing plants, and chemical processing units. Its standard footprint (typically 2000*800*1800 mm) and flexible working width accommodate a range of industrial setups.Q: What safety features are included in the Salt Soda Ash Dispensing System?

A: Safety features include an emergency stop button, overload protection, and an interlocking system to prevent accidental or unsafe operation. These measures protect both operators and equipment, ensuring reliable and secure daily use.Q: How can users benefit from this dispensing solution?

A: By offering fully-automatic operation, high precision, dust-free handling, and low maintenance, this system increases productivity and reduces operational hazards. Its corrosion-resistant build ensures longevity, minimizing downtime and total cost of ownership for industrial users.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Dispensing System for Chemical & Powder Dyestuff' category

We export in USA Indonesia, Vietnam, Bangladesh, Ethiopia, Uzbekistan, Sri Lanka, Philippines, Turkey and Mexico.

|

R. B ELECTRONIC & ENGINEERING PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese