Chemical Dosing Dispenser System

200000.00 - 500000.00 INR/Unit

Product Details:

- Temperature Range Ambient to 50C

- Working Width Customizable as per requirement

- Condition New

- Heat Source NA (ambient/none required)

- Control System PLC Based Automatic Control

- Noise Level < 65 dB

- Machine Type Chemical Dosing Dispenser System

- Click to View more

X

Chemical Dosing Dispenser System Price And Quantity

- 200000.00 - 500000.00 INR/Unit

- 1 Unit

Chemical Dosing Dispenser System Product Specifications

- Ambient to 50C

- Customizable as per requirement

- PLC Based Automatic Control

- NA (ambient/none required)

- New

- 220V - 240V AC, 50 Hz

- Chemical Dosing Dispenser System

- < 65 dB

- Precision Dosing, User-programmable Recipes, Automatic and Manual Operation, Anti-leakage Protection, Real-time Monitoring, and Display Panel

- Approx. 120 kg

- Variable as per dosing program

- 1 to 6 Bar

- 2024

- Up to 500 liters/hour

- Electric Pump Driven

- Suitable for liquid chemicals for textile, laundry or industrial processes

- 1200 x 500 x 1300 mm (approx.)

- Automatic Dosing Unit

Chemical Dosing Dispenser System Trade Information

- 10 Unit Per Month

- 2-12 Week

- All India

Product Description

Chemical Dosing Dispenser System supplies chemical needed for your processes just-in-time to the right place in correct quantities with high accuracy. The designed system parts allows 24 hour non-stop operation.

Features:

- Automatic Dosing & Dispensing of liquid chemicals

- Independent Control Unit makes it quick & safe

- Easy Assembling

- Minimum service & maintenance due to special design

- Detailed reporting

- Valve leakage test system

- Remote connectivity & Software update

- Touch Screen

- Report & analysis Software

Precision and Flexibility for Modern Industries

This dispenser offers customizable working widths and variable speed programs, adapting to a range of industrial applications. The system is equipped with user-programmable recipes and supports both manual and automatic operation, ensuring precise control over dosing for textiles, water treatment, laundry, pharmaceuticals, and more.

Comprehensive Safety and Monitoring Features

Engineered for safety and reliability, the system integrates emergency stops, overload protection, anti-leakage measures, and low-level alarms. Real-time performance is displayed via a touchscreen HMI, and remote monitoring is supported for ongoing operational transparency.

Effortless Installation and Maintenance

The units plug & play skid-mounted design ensures simplified installation in diverse facilities. Maintenance is streamlined with tool-less access to pumps and valves, while durable polypropylene or SS316 tanks minimize downtime and extend operational life.

FAQs of Chemical Dosing Dispenser System:

Q: How does the Chemical Dosing Dispenser System ensure precise dosing accuracy?

A: The system uses electric pump-driven dosing channels controlled by a PLC-based automatic control unit, achieving dosing accuracy of 1% per cycle. User-programmable recipes and real-time monitoring on the HMI panel allow for consistent and repeatable chemical dosing outcomes.Q: What types of chemicals and industries is this dispenser suitable for?

A: Engineered with high-grade polypropylene or SS316 tanks, the system is ideal for handling liquid chemicals used in textile processing, water treatment, laundry, pharmaceutical, food & beverage, and paper industries. It accommodates a wide variety of industrial chemical dosing needs.Q: Where can the Chemical Dosing Dispenser System be installed, and how is installation managed?

A: This dispenser is delivered in a skid-mounted, plug & play format, allowing for quick and easy installation in plants or facilities. Its compact design and customizable dimensions suit a variety of operational spaces, making it adaptable for new or existing industrial settings.Q: When should maintenance be performed, and how accessible is it?

A: Routine maintenance is minimal due to the units robust design and quality components. Operators can access pumps and valves without special tools, ensuring efficient maintenance schedules and minimized downtime.Q: What safety features help protect operators and ensure safe operation?

A: Safety is addressed through emergency stop buttons, overload protection, a leak-proof construction, integrated low-level sensors with alarms, and anti-leakage systems. These collectively mitigate risks and promote secure operation in industrial environments.Q: How does the system support real-time monitoring and remote management?

A: A touchscreen HMI displays real-time operating data, enabling immediate oversight. Connectivity options including RS485/Modbus and remote access allow for remote monitoring and control, enhancing efficiency for facility managers.Q: What are the key benefits of using this dosing system in industrial processes?

A: Key benefits include precise, reliable dosing; high production capacity; low noise (<65 dB); energy-efficient electric pump operation; easy maintenance; and robust safety features. The systems versatility and automation help enhance productivity and process consistency across multiple industries.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

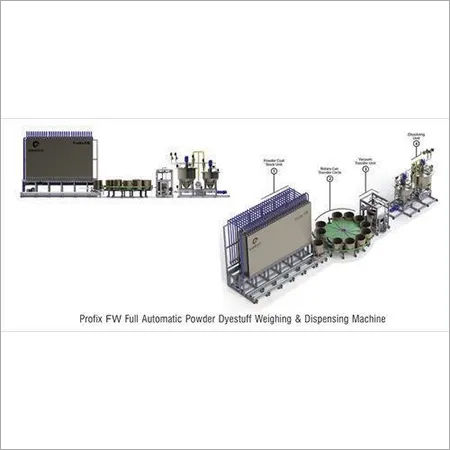

Other Products in 'Dispensing System for Chemical & Powder Dyestuff' category

We export in USA Indonesia, Vietnam, Bangladesh, Ethiopia, Uzbekistan, Sri Lanka, Philippines, Turkey and Mexico.

|

R. B ELECTRONIC & ENGINEERING PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese