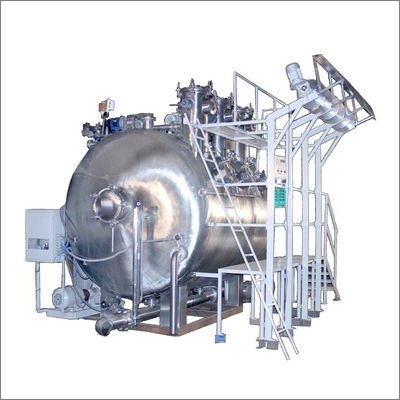

HTHP Soft Flow Dyeing Machine

Product Details:

- Condition New

- Speed Adjustable (variable based on fabric type)

- Usage & Applications Dyeing of various fabric types, Ideal for textile processing mills, Suitable for bulk and small-batch dyeing

- Temperature Range Up to 140C

- Type HTHP Soft Flow Dyeing Machine

- Dimension (L*W*H) 5300 mm x 2100 mm x 2800 mm (approx.)

- Applicable Material Cotton, Polyester, Blends, Viscose, Nylon

- Click to View more

X

HTHP Soft Flow Dyeing Machine Product Specifications

- Low liquor ratio, Eco-friendly process, High automaton, Energy efficient, Low maintenance, Smooth fabric movement

- 5300 mm x 2100 mm x 2800 mm (approx.)

- 1 or more (customizable)

- Centrifugal / High Flow Pump

- New

- Dyeing of various fabric types, Ideal for textile processing mills, Suitable for bulk and small-batch dyeing

- Up to 140C

- Variable (depends on model size)

- Adjustable (variable based on fabric type)

- HTHP Soft Flow Dyeing Machine

- High Temperature High Pressure Soft Flow Dyeing Machine

- Knitted, Woven, Delicate and Synthetic Fabric

- Up to 2400 mm

- Cotton, Polyester, Blends, Viscose, Nylon

- 380 V / 415 V / 50 Hz

- 2024

- Approx. 3000 kg (varies with capacity)

- 7.5 kW - 15 kW (depending on model)

- 50 kg to 1000 kg per batch

- PLC Automatic Control

Product Description

The HTHP (High-Temperature High-Pressure) Soft Flow Dyeing Machine is a type of dyeing machine used in textile industries for dyeing fabrics, yarns, and other textile materials. This machine uses a combination of soft-flow and high-pressure techniques to ensure even and thorough dyeing of the textile materials.HTHP Soft Flow Dyeing Machine has a stainless steel construction, which makes it durable and resistant to corrosion. The design is compact and energy-efficient, ensuring low power consumption and reduced operational costs. The machine has a user-friendly control panel that allows operators to adjust the dyeing parameters such as temperature, pressure, and time.

Advanced Dyeing Technology for Textile Processing

Our HTHP Soft Flow Dyeing Machine features cutting-edge automation, digital controls, and a high-efficiency design. With capabilities to handle various fabric types and low liquor consumption, this system ensures optimal resource utilization and consistent dyeing results. Engineered for ease of maintenance and energy savings, it suits both large-scale and small-batch textile operations.

Comprehensive Safety and User-Friendly Operation

Safety is paramount; the machine is equipped with a pressure relief valve, automatic door interlock system, and over-temperature protection, ensuring secure operation. The intuitive digital HMI touchscreen allows operators to monitor and adjust all parameters easily, enhancing productivity and minimizing operational risks.

Customizable and Application-Focused Design

Available in different models to accommodate diverse capacity needs, the HTHP Soft Flow Dyeing Machine supports both woven and knitted fabrics, with flexible chamber configurations and multiple inlets for water and chemicals. Its eco-friendly and insulated design helps in maintaining temperature stability and minimizing energy loss.

FAQ's of HTHP Soft Flow Dyeing Machine:

Q: How does the HTHP Soft Flow Dyeing Machine maintain efficient dyeing with a low liquor ratio?

A: The machine is designed with advanced flow management and high-efficiency pumps to circulate dye liquor effectively. Its low liquor ratio of 1:4 to 1:6 optimizes water and chemical usage, ensuring even dye penetration while reducing resource consumption and environmental impact.Q: What types of fabrics and materials can be processed with this machine?

A: This dyeing machine is suitable for a wide range of fabrics, including knitted, woven, delicate, and synthetic textiles such as cotton, polyester, blends, viscose, and nylon. The adjustable speed and smooth fabric movement system ensure high-quality results for each material type.Q: When is on-site service and support provided?

A: On-site installation, operator training, and after-sales support are offered as part of our comprehensive service package, ensuring that customers can start production smoothly and maintain optimal machine performance.Q: Where can the HTHP Soft Flow Dyeing Machine be installed?

A: This machine is designed for use in textile processing mills, dyeing units, and facilities handling both bulk and small-batch production. It is suitable for installation in exporter, manufacturer, or supplier operations throughout India and internationally.Q: What is the typical dyeing process on this machine?

A: The process involves loading the required fabric, selecting the recipe via the PLC automatic control interface, and letting the machine manage temperature, chemical dosing, and pressure automatically. The system ensures even heating, eco-friendly operation, and safe handling through integrated safety systems and advanced automation.Q: What benefits does the digital touch screen interface offer?

A: The digital HMI touch screen interface provides real-time monitoring and easy adjustment of process parameters, enabling operators to optimize operational efficiency, maintain precise control, and reduce downtime. It enhances user experience and streamlines workflow.Q: How does the safety system ensure secure operation?

A: The safety system includes a pressure relief valve, an automatic door interlock to prevent opening under pressure, and over-temperature protection. Together, these features safeguard operators and equipment during all stages of the dyeing cycle.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Soft Overflow Dyeing Machine' category

We export in USA Indonesia, Vietnam, Bangladesh, Ethiopia, Uzbekistan, Sri Lanka, Philippines, Turkey and Mexico.

|

R. B ELECTRONIC & ENGINEERING PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Call Me Free

Call Me Free

Call Me Free

Call Me Free