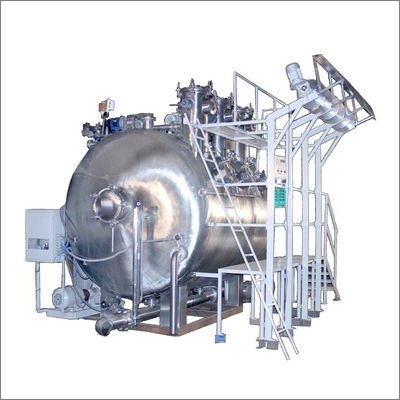

SS Soft Overflow Dyeing Machine

Product Details:

- Capacity 100 kg to 1000 kg per batch

- Control Type PLC Based Automatic Control

- Speed Variable (adjustable) up to 300 RPM

- Voltage 380V / 415V (Three Phase)

- Usage & Applications For dyeing polyester, cotton, viscose, blended fabrics and delicate textile materials

- Manufacturing Year 2023

- Condition New

- Click to View more

X

SS Soft Overflow Dyeing Machine Product Specifications

- 2023

- For dyeing polyester, cotton, viscose, blended fabrics and delicate textile materials

- New

- Automatic Overflow Dyeing Machine

- Up to 140C

- Soft Overflow Dyeing Machine

- PLC Based Automatic Control

- Variable (adjustable) up to 300 RPM

- 380V / 415V (Three Phase)

- Woven, Knitted, Delicate and Synthetic Fabrics

- Stainless Steel (SS 304/316L)

- Customized as per requirement

- Stainless Steel Centrifugal Pump

- 7.5 kW

- 100 kg to 1000 kg per batch

- Up to 2400 mm

- Low Liquor Ratio, High Efficiency, Gentle Fabric Treatment, Energy Saving, User-friendly Operation

- 600 L to 6000 L

- 1 to 3 (as per model)

- Approx. 1800 kg

Product Description

SS Soft Overflow Dyeing Machine is a type of dyeing machine used in textile industries for dyeing fabrics, yarns, and other textile materials. The machine uses the principle of a continuous dyeing process, where the textile materials are continuously fed into the dyeing chamber and passed through a series of overflow dyeing tanks.The machine has a stainless steel construction, which makes it durable and resistant to corrosion. The design is compact and energy-efficient, ensuring low power consumption and reduced operational costs.

Exceptional Fabric Compatibility

This dyeing machine handles a diverse range of textile materials-including polyester, cotton, viscose, blends, and delicate synthetic fabrics. Its gentle overflow process protects fiber integrity, making it suitable for technical and high-value textiles. Adjustable speed and batch capacity allow adaptation to different production demands, making it ideal for both small- and large-scale manufacturers.

Energy-Efficient, Low Liquor Ratio Design

Operating at a low liquor ratio of 1:4 to 1:6, this overflow dyeing machine enables significant water and chemical savings. Its high-grade thermal insulation and intelligent dosing system further improve energy efficiency and fabric processing consistency, delivering high-quality results with reduced operating costs.

Advanced User-Focused Automation

Equipped with a modern PLC-based control system and intuitive touchscreen HMI, the machine simplifies operation, recipe management, and monitoring. Automated dosing, customizable dimensions, and user-friendly maintenance features streamline workflow, minimize manual effort, and ensure reliable performance batch after batch.

FAQ's of SS Soft Overflow Dyeing Machine:

Q: How does the SS Soft Overflow Dyeing Machine ensure gentle treatment of delicate fabrics?

A: The machine features a soft overflow dyeing process and adjustable speed up to 300 RPM, which gently circulates fabrics while minimizing mechanical stress. This design is suitable for delicate and synthetic materials, reducing the risk of damage or creasing during dyeing.Q: What types of fabrics and materials can be processed with this machine?

A: It is specifically designed for woven, knitted, blended, and synthetic fabrics, including polyester, cotton, viscose, and delicate textile materials. The robust construction and versatile settings allow it to accommodate a variety of fabric widths up to 2400 mm.Q: When is the automatic dosing system used, and why is it beneficial?

A: The automatic dosing system operates during dyeing cycles to precisely add chemicals and colors, ensuring even distribution and consistent color quality. This automation improves process reliability, reduces manual intervention, and enhances safety by minimizing chemical handling.Q: Where can the SS Soft Overflow Dyeing Machine be installed?

A: The machine is designed as a floor-mounted unit with customizable dimensions, making it adaptable for installation in textile mills, dye houses, and industrial settings. Its CE certification and ISO 9001:2015 approval ensure compliance with industry standards globally.Q: What process control features are available for operation and monitoring?

A: It includes a PLC-based automation system with a digital touchscreen HMI for easy programming, process monitoring, and control. Multiple safety features-such as overheat protection, a pressure relief valve, and emergency stop-ensure safe and efficient operation.Q: How is maintenance managed, and what features make it convenient?

A: Maintenance is simplified through accessible service points, robust stainless-steel construction, and high-sealing gaskets that prevent leaks. These features facilitate easy cleaning and routine upkeep, ensuring long-term durability and minimal downtime.Q: What are the main benefits of using this dyeing machine in textile production?

A: Key benefits include low noise operation (<75 dB), significant water and energy savings, gentle fabric care, automatic dosing, reliable safety systems, and compliance with international quality standards. These elements contribute to enhanced productivity, product quality, and cost efficiency.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Soft Overflow Dyeing Machine' category

We export in USA Indonesia, Vietnam, Bangladesh, Ethiopia, Uzbekistan, Sri Lanka, Philippines, Turkey and Mexico.

|

R. B ELECTRONIC & ENGINEERING PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese