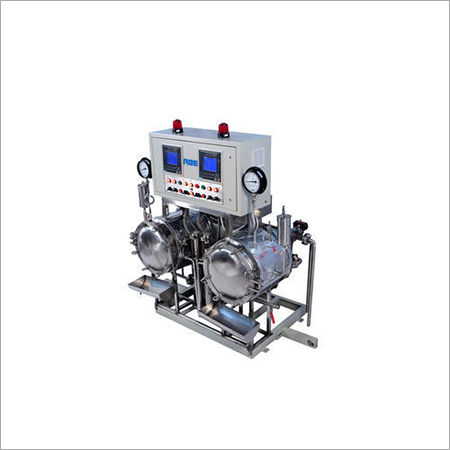

Yarn Heat Setting Machine

Product Details:

- Weight Approx. 2500 kg

- Dimension (L*W*H) 6000x2200x2200 mm

- Manufacturing Year 2022

- No Of Chamber 2

- Type Yarn Heat Setting Machine

- Fabric width Up to 500 mm

- Usage & Applications Heat setting, texturizing and processing of yarn bobbins/cheese

- Click to View more

Yarn Heat Setting Machine Price And Quantity

- 1 Unit

- 330000.00 - 600000.00 INR/Unit

Yarn Heat Setting Machine Product Specifications

- New

- Yarn (Synthetic / Blended / Wool)

- PLC Controlled

- Up to 100 m/min

- Heat setting, texturizing and processing of yarn bobbins/cheese

- 800-1000 kg/day

- Customizable

- Fully Automatic

- Polyester, Nylon, Acrylic, Wool

- Up to 220C

- Uniform heat distribution, energy efficient, user-friendly interface

- Approx. 2500 kg

- Centrifugal/Recirculation

- 20 kW

- Up to 500 mm

- 380-415 V

- Yarn Heat Setting Machine

- 2

- 2022

- 6000x2200x2200 mm

Yarn Heat Setting Machine Trade Information

- 10 Unit Per Month

- 2-12 Week

Product Description

MCY-4 controller regulated Yarn Heat Setting Machines have been designed as per global norms. Developed from mild steel or 316/304 grade stainless steel, these equipments use maximum 65 cm of mercury. Provided Yarn Heat Setting Machines are accessible in three phase design. These consume 415 v voltage and their frequency is 50Hz. Provided equipments can endure maximum 0.07 MPa operating pressure and up to 120 degree C working temperature. Their maximum installation capacity is 150 kg steam/ton. We offer these systems at reasonable price.

Product details

Minimum Order Quantity | 1 Unit Onwards |

Automation | Through MCY-4 Controller |

Vacuum upto | 65 cm Of Mercury |

Material Of Construction | MS/SS 304/SS 316 |

Electrical Supply | 415 V, Three phase 50Hz |

Precision and Efficiency for Yarn Processing

With a capacity of up to 1000 kg per day and speeds reaching 100 meters per minute, this Yarn Heat Setting Machine is built for high-volume, consistent output. The forced air system ensures homogeneous heat distribution throughout the chambers, maintaining precise temperature control. A touch screen HMI combined with PLC control enables intuitive operation and monitoring, making it user-friendly for various industrial applications.

Enhanced Safety and Reliable Operation

Operator safety is paramount, with features like overload protection, emergency stop buttons, and thermal cut-off preventing accidental damage and hazards. The robust construction, advanced recirculation system, and energy-efficient design ensure reliable, long-lasting performance. With customizable volume and dimensions, the machine fits diverse manufacturing needs, and on-site support ensures smooth installation and commissioning.

FAQs of Yarn Heat Setting Machine:

Q: How does the Yarn Heat Setting Machine ensure uniform heat distribution across processed yarns?

A: The machine employs a forced air circulation system and precision-controlled heating, either by electric or thermic fluid, to deliver consistent temperatures throughout the chambers. This guarantees uniform heat distribution across all yarn bobbins or cheese during processing.Q: What types of yarn materials can be processed with this heat setting machine?

A: This machine is suitable for synthetic, blended, and wool yarns, specifically including polyester, nylon, acrylic, and wool. The system can handle fabric widths up to 500 mm, covering a wide range of yarn applications.Q: When is it advisable to request service or maintenance support for the machine?

A: Routine maintenance is recommended as per the manufacturers guidelines. Should any technical issues arise, such as irregular temperature control or abnormal noises, service support is available upon request to maintain optimal performance.Q: Where can the Yarn Heat Setting Machine be installed, and is on-site support provided?

A: This machine is designed for industrial use and should be installed in facilities processing yarns or textiles. On-site installation support is available to ensure proper setup and commissioning, facilitating a seamless start to operations.Q: What is the process for operating the machine, and is technical training provided?

A: Operation is managed via a touch screen HMI with PLC control, making the process user-friendly. After installation, operators can easily set temperature, speed, and monitoring parameters. On-site training or support may be provided to familiarize staff with all features and safety protocols.Q: How do the safety features benefit the operator and the machines lifespan?

A: Equipped with overload protection, emergency stop, and thermal cut-off, the machine prioritizes operator safety and prevents equipment damage. These systems minimize downtime, reduce risk of accidents, and contribute to the longevity of the machine.Q: What are the primary benefits of using a fully automatic Yarn Heat Setting Machine for manufacturing?

A: A fully automatic system enhances productivity, maintains consistent product quality, reduces human error, and optimizes energy usage. With precise temperature control and customizable settings, it streamlines yarn processing for diverse industrial requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Dye House Automation' category

|

R. B ELECTRONIC & ENGINEERING PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Call Me Free

Call Me Free

Call Me Free

Call Me Free