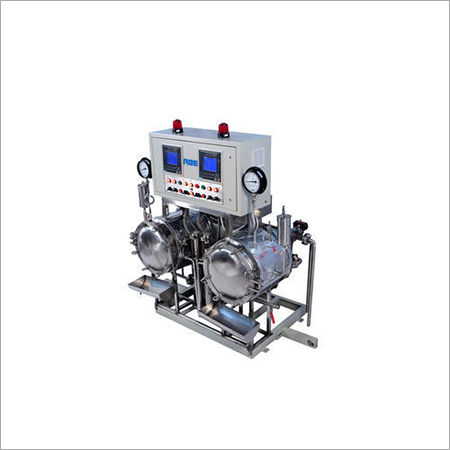

Pneumatic Padding Mangle

Product Details:

- Pump Type Pneumatic Pump

- Manufacturing Year 2024

- Type Pneumatic Padding Mangle

- Fabric Type Woven and Non-woven Fabrics

- Speed Variable, up to 40 m/min

- Control Type Automatic with Digital Display

- No Of Chamber Single Chamber

- Click to View more

Pneumatic Padding Mangle Price And Quantity

- 330000.00 - 600000.00 INR/Unit

- 1 Unit

Pneumatic Padding Mangle Product Specifications

- Up to 1800 mm

- New

- Anti-corrosive body, Easy maintenance, Consistent pressure application

- 415 V, 3 Phase, 50 Hz

- 4 kW

- Industrial Textile Finishing Equipment

- 2600 x 1300 x 1600 mm

- Continuous Operation

- Cotton, Polyester, Blends

- Ambient to 80C

- Approx. 1200 kg

- Pneumatic Pump

- Pneumatic Padding Mangle

- 2024

- Woven and Non-woven Fabrics

- Automatic with Digital Display

- Variable, up to 40 m/min

- Used in textile mills for dyeing, finishing, and chemical application on fabric

- Single Chamber

Pneumatic Padding Mangle Trade Information

- 10 Unit Per Month

- 2-12 Week

Product Description

This Pneumatic Padding Mangle is used for producing auxiliary agent and dyes. This machine can maintain 450 mm to 600 mm working width range. Its weight ranges between around 220 kg to 240 kg. Operating pressure of this equipment is 4 kg/cm2. Developed from 316/304 grade stainless steel, provided Pneumatic Padding Mangle has 50 hz frequency. Its dimension is 1060 mm x 650 mm x 790 mm. Hardness of its bowl ranges between 65 degree to 70 degree shore. Long working life is one of its main aspects.

Product details

Minimum Order Quantity | 1 Unit Onwards |

Approx Weight | 220 -240 kg |

Working width | 450, 600mm |

Working Pressure | 4Kg/Cm2 |

Unheated trough Capacity | 200ml |

Material of construction | SS 304 & SS 316 |

Heated Trough's Capacity | 900ml |

Frequency | 50 Hz |

Dimension | L1060 mm x W650 mm x H790 mm |

Cloth Speed | Variable upto 3 Mtr / Min |

Bowl hardness | 65-70 Degree Shore Hardness |

Precision Textile Finishing Technology

The Pneumatic Padding Mangle utilizes a smooth, non-stick rubber-coated steel roller to deliver uniform and precise finishing to a variety of textile materials. Its variable speed (up to 40 m/min) and adjustable pneumatic pressure ensure reliable performance for continuous operations, making it highly suitable for dyeing, finishing, and chemical applications in demanding mill environments.

Engineered for Safety and Durability

This machine features advanced safety mechanisms such as emergency stop and overload protection, safeguarding operators during high-speed production. The anti-corrosive body ensures long-lasting durability, while low noise emission (<70 dB) creates a more comfortable working environment. Easy maintenance and straightforward controls further extend machine lifespan and minimize downtime.

Flexible Control and Adaptability

Automatic digital control simplifies operation and maintains production consistency. The pneumatic pressure system adapts easily to different fabric types-cotton, polyester, and blends-accommodating widths up to 1800 mm. With the option for a hydraulic system, this mangle provides extra flexibility for custom requirements in textile production facilities.

FAQ's of Pneumatic Padding Mangle:

Q: How does the pneumatic padding mangle apply pressure to fabrics?

A: The machine uses a pneumatic system that allows for precise, adjustable pressure (0-6 bar) to be applied evenly across the fabric through a smooth, rubber-coated steel roller. This ensures optimal results for dyeing, finishing, and chemical application.Q: What types of fabrics and materials can be processed with this mangle?

A: It is designed for both woven and non-woven textiles, compatible with cotton, polyester, and various blended fabrics. The large roller width accommodates fabrics up to 1800 mm, making it versatile for different production needs.Q: When should the emergency stop or overload protection be used?

A: Operators should use the emergency stop feature whenever an urgent safety concern arises during operation, while overload protection automatically activates if the machine experiences excessive load, preventing equipment damage and ensuring worker safety.Q: Where is the ideal installation location for this machine?

A: The Pneumatic Padding Mangle is floor-mounted and intended for industrial settings, such as textile factories or mills, where robust infrastructure and three-phase power (415 V, 50 Hz) are available.Q: What is the maintenance process for this machine?

A: Routine maintenance involves checking pneumatic connections, ensuring roller surfaces remain clean and non-stick, and verifying that safety features and the digital control system function properly. The anti-corrosive design facilitates minimal upkeep and consistent performance.Q: How does the variable speed and automatic control benefit production?

A: The AC motor with inverter drive allows variable fabric speeds up to 40 m/min, while the automatic digital display ensures consistent and accurate control of operating parameters, resulting in high-quality, repeatable finishes with minimal manual intervention.Q: What are the key advantages of using this padding mangle in textile finishing applications?

A: Key benefits include consistent pressure application, smooth and non-stick rollers for better fabric treatment, easy adaptability for various fabric types, enhanced operator safety, and reliable long-term operation due to its robust, anti-corrosive construction.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Dye House Automation' category

|

R. B ELECTRONIC & ENGINEERING PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese