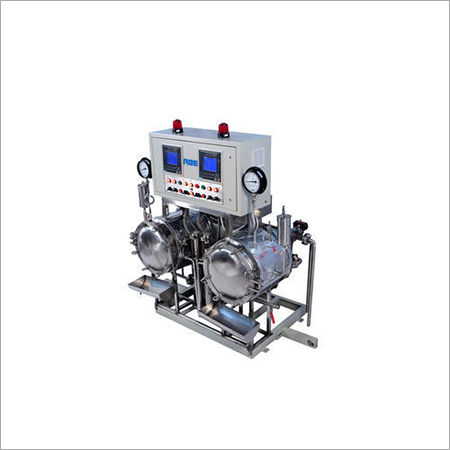

Yarn Conditioning Machine

330000.00 - 600000.00 INR/Unit

Product Details:

- Weight Approx. 1200 kg

- Power 7.5 kW

- Fabric Type Yarn Package

- Speed Variable

- Control Type PLC Control

- Features Energy Efficient, Automatic Humidity Control, Stainless Steel Construction, Digital Display

- Dimension (L*W*H) 2800 x 1700 x 2200 mm

- Click to View more

X

Yarn Conditioning Machine Price And Quantity

- 330000.00 - 600000.00 INR/Unit

- 1 Unit

Yarn Conditioning Machine Product Specifications

- Up to 500 kg/Batch

- 2023

- 1

- New

- Polyester, Cotton, Blends

- Yarn Conditioning, Humidity Treatment, Textile Finishing

- Semi-Automatic

- Yarn Conditioning Machine

- 415 V

- Vacuum Pump

- 1500 L

- PLC Control

- Energy Efficient, Automatic Humidity Control, Stainless Steel Construction, Digital Display

- 2800 x 1700 x 2200 mm

- Up to 99C

- Approx. 1200 kg

- 7.5 kW

- Variable

- Yarn Package

Yarn Conditioning Machine Trade Information

- 10 Unit Per Month

- 2-12 Week

Product Description

Specification

Minimum Order Quantity | 1 Unit Onwards |

Automation | Through MCY-4 Controller |

Brand | RBE |

Machine Type | Automatic |

Vacuum upto | 65 cm. Of Mercury |

Temperature range | upto 130 Degree C |

Maximum Pressure | 4kg./cm sq. |

Material Of Construction | MS/SS 304/SS 316 (As per customer requirement) |

Electrical Supply | 415V,Three phase 50Hz |

Connecting Load | 3 Kw to 20 Kw |

Superior Yarn Conditioning Performance

Engineered for excellence, the machine's electric steam heater ensures precise humidity and temperature management, supporting up to 95% RH and 99C. Its variable speed and PLC automation accommodate a wide range of yarn substrates, making it suitable for diverse textile manufacturing needs. Stainless steel construction enhances both lifespan and hygiene.

Advanced Safety and User-Friendly Design

Featuring automatic pressure release, over-temperature safeguards, and a digital LED display, this machine prioritizes operator safety and ease of use. Manual and automated operation modes, coupled with real-time monitoring, ensure optimal performance while minimizing risks during processing.

FAQ's of Yarn Conditioning Machine:

Q: How does the Yarn Conditioning Machine benefit my textile production process?

A: It optimizes yarn moisture content and flexibility, improving the overall quality, dye uptake, and finishing of textiles. The automated humidity and temperature controls ensure uniform conditioning, leading to consistent product performance.Q: What materials can be processed in this machine?

A: The machine is designed to handle polyester, cotton, and blended yarn packages. Its robust construction and adjustable controls make it suitable for a range of yarn types used in textile manufacturing.Q: When and where is it best to use this Yarn Conditioning Machine?

A: This machine is ideal for textile finishing stages where precise moisture and temperature conditioning are necessary. It's especially beneficial before dyeing, weaving, or winding operations, and is suitable for industries across India and global export markets.Q: What is the typical operating process for this machine?

A: Load up to 500 kg of yarn packages, select the desired settings on the PLC or manual controls, and the machine manages the cycle, reaching up to 99C and 95% humidity. The integrated vacuum and safety systems monitor the operation, which completes in 60-120 minutes.Q: How easy is the machine to maintain and operate?

A: With its automatic features, digital display, and robust stainless steel build, the machine requires minimal maintenance. Its user-friendly interface and low-maintenance design help ensure smooth operation and reduce downtime.Q: What safety features are included in the Yarn Conditioning Machine?

A: The machine includes an automatic pressure release valve, over-temperature protection, emergency stop button, and a PLC control system to safeguard both the equipment and operators during operation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Dye House Automation' category

We export in USA Indonesia, Vietnam, Bangladesh, Ethiopia, Uzbekistan, Sri Lanka, Philippines, Turkey and Mexico.

|

R. B ELECTRONIC & ENGINEERING PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Call Me Free

Call Me Free

Call Me Free

Call Me Free