Enmos Dyeing Controller - Simplex 263

166000.00 - 186000.00 INR/Piece

Product Details:

- Connection RS232/RS485, digital and analog I/O

- Pressure 0-6 bar measurement range

- Accuracy 0.1C temperature accuracy

- Function Textile dyeing process control

- Size 160 x 90 x 85 mm (front panel)

- Click to View more

X

Enmos Dyeing Controller - Simplex 263 Price And Quantity

- 1 Piece

- 166000.00 - 186000.00 INR/Piece

Enmos Dyeing Controller - Simplex 263 Product Specifications

- 160 x 90 x 85 mm (front panel)

- RS232/RS485, digital and analog I/O

- 0-6 bar measurement range

- 0.1C temperature accuracy

- Textile dyeing process control

Enmos Dyeing Controller - Simplex 263 Trade Information

- 10 Piece Per Month

- 2-12 Week

Product Description

Simplex 520 is a model from Enmos Simplex Family controllers / PLC. Controller Simple 520 is capable of operating different types of fully automatic machines with their special commands for processes.Features of Enmos Dyeing Controller - Simplex 263:

- Easy-to-use 800 x 480 Color TFT screen (256.000 colors)

- Quick access to commands & sub-menus

- 3 Level password Protection

- Reports for occurred alarms

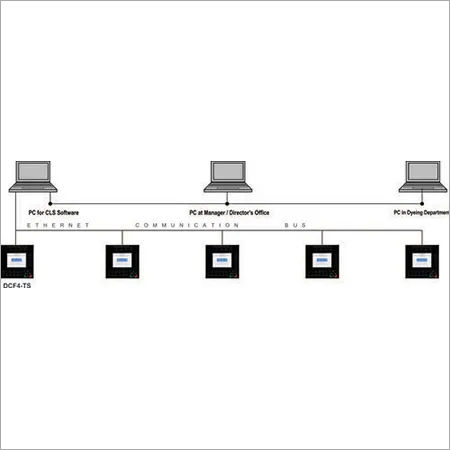

- Fully integrated into Focus (Enmos Central Monitoring Software)

- Easy project management with SPM (Simplex Project Manager)

- Programmable parametric security limitations

- Consumptions Reports

- Easy project copying via SD/MMC card

- Report control support with VNC

- Ability to enter password protected command, alarm & system parameters Ability to handle calibrations from different points

Precision Control for Textile Dyeing

Engineered for demanding textile environments, the Simplex 263 provides unparalleled accuracy with 0.1C temperature measurement. Compatible with both PT-100 and thermocouple sensors, it adapts easily to diverse process requirements. Designed for reliability, its alarm systems and robust construction help prevent costly errors during dyeing.

Intuitive Operation with Advanced Features

The user-friendly membrane keypad and detailed LED display support efficient operation and monitoring. A panel-mount system facilitates space-saving installation, while multiple output options and communications ports ensure flexible integration with other manufacturing systems. Its protective front panel (IP54) safeguards against dust and moisture.

FAQs of Enmos Dyeing Controller - Simplex 263:

Q: How do I install the Enmos Dyeing Controller - Simplex 263?

A: The controller is designed for panel mounting and should be securely fitted into a standard control panel cutout (160 x 90 mm front size). Ensure all wiring and sensor connectionssuch as PT-100, thermocouple, input/output terminals, and power supplyare made as per the user manual to guarantee safe and efficient operation.Q: What are the key benefits of using the Simplex 263 in textile dyeing processes?

A: This controller offers precise temperature and pressure control, ensuring consistent dyeing results and reducing waste or rework. Its fast and visual 4-digit LED display, along with accurate sensors, allow operators to monitor and adjust parameters with ease. Alarm features also provide added operational safety.Q: When is the controllers alarm function triggered?

A: The Simplex 263s visual and audible alarms activate when temperature or pressure readings exceed preset limits, or if there is a process or sensor fault. This helps users quickly address issues, minimizing downtime and preventing damage to textiles or machinery.Q: What process parameters can the Simplex 263 monitor and control?

A: It monitors and controls temperature (0C to 150C) and pressure (0-6 bar), ensuring that textile dyeing processes remain within the optimal range. The controller manages these variables through programmable setpoints and precise analog or relay outputs.Q: Where can the Simplex 263 be deployed within a textile facility?

A: It is suitable for installation in any dyeing process line within textile plants, particularly in environments where precise temperature and pressure regulation is essential. Its compact and protected design (IP54 front) makes it ideal for demanding factory settings.Q: How does the controller connect with other systems?

A: The Simplex 263 offers RS232/RS485 communication ports, as well as digital and analog I/O connections. This enables seamless integration with factory automation systems, data logging devices, or remote monitoring setups to improve process management and traceability.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'RBE Dyeing Machine Controller' category

We export in USA Indonesia, Vietnam, Bangladesh, Ethiopia, Uzbekistan, Sri Lanka, Philippines, Turkey and Mexico.

|

R. B ELECTRONIC & ENGINEERING PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese