Central Link System

166000.00 - 186000.00 INR/Piece

Product Details:

- Connection Butt Welded / Socket / Threaded

- Accuracy High precision molding ensures leak-proof connections

- Pressure Up to 20 bar

- Function Connects main and lateral pipes for efficient water distribution

- Size 63 mm to 180 mm

- Click to View more

X

Central Link System Price And Quantity

- 1 Piece

- 166000.00 - 186000.00 INR/Piece

Central Link System Product Specifications

- High precision molding ensures leak-proof connections

- Connects main and lateral pipes for efficient water distribution

- 63 mm to 180 mm

- Butt Welded / Socket / Threaded

- Up to 20 bar

Central Link System Trade Information

- 10 Piece Per Month

- 2-12 Week

Product Description

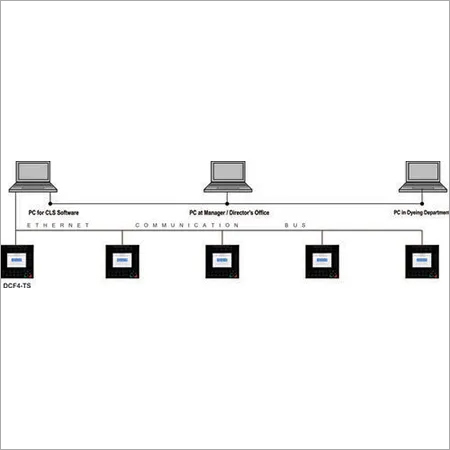

R. B Electronic & Engineering Pvt. Ltd. designs and develops an RBE series of controller/ PLC for dye machine. There are four different models under the RBE series. One model is a software that can be used for centralizing and connecting dyeing controller to a single Personal Computer. Central Link System (CLS) is that software that can be installed to transfer data between the controllers and Personal Computer. It is convenient to enter the programs in the Personal Computer, and transfer them to any individual controller. It is possible to store as many programs in the Personal Computer.

Features:

- It comes with a multi user facility

- The software is password protected, so that only operator, supervisor, manager/ director can use it.

- It creates MIS Management Information Reports- for Productivity, Machine utilization, Operator performance, Water Consumption, Alarms& many others

- It creates a real time online process graph for every machine

Reliable Water Distribution Solution

The Central Link System offers a robust platform for connecting main pipelines to lateral branches, ensuring optimal water flow management. Its use of premium PVC, HDPE, or PP enhances resilience, while high-precision molding guarantees leak-proof performance in all installations. Designed for both intensive agricultural irrigation and municipal water supply applications, it stands up to demanding operational environments.

Engineered for Durability and Compliance

Each Central Link System component meets IS:4984 standards, ensuring safety and regulatory compliance. These connectors are UV stabilized, making them suitable for prolonged outdoor exposure, resisting degradation from sunlight. The corrosion-resistant materials and high pressure tolerance up to 20 bar reinforce their endurance in challenging field conditions, ensuring long service life with minimal maintenance requirements.

FAQs of Central Link System:

Q: How is the Central Link System installed in irrigation or water supply networks?

A: The Central Link System features an easy and fast assembly, utilizing butt welded, socket, or threaded connections. Its precise molding allows for straightforward integration with main and lateral pipes, ensuring reliable leak-proof joints. Typical installation does not require special tools, which helps reduce setup time and labor costs.Q: What materials are used in manufacturing the Central Link System, and how do they enhance performance?

A: Manufactured from high-quality PVC, HDPE, or PP, the Central Link System offers excellent strength, chemical resistance, and longevity. These materials are UV stabilized, providing superior protection against sunlight damage and ensuring the system remains durable and reliable even in harsh outdoor conditions.Q: When should the Central Link System be used in a project?

A: The system is ideal when constructing or upgrading irrigation, agriculture, or municipal water supply networks. Its suitable for situations that demand reliable, high-pressure pipelines, particularly where compliance with Indian standards (IS:4984) is required and long-term durability in environmental exposure is necessary.Q: Where can the Central Link System be applied effectively?

A: This system is widely used across a variety of environments in India and internationally, including farms for crop irrigation, municipal water supply infrastructures, and other projects demanding efficient water distribution under varying environmental conditions.Q: What is the process for ensuring leak-proof connections with the Central Link System?

A: Each connector is manufactured with high-precision molding, which ensures tight, accurate fittings for leak-proof assembly. Following the specified connection methodwhether butt welded, socket, or threadedguarantees effective sealing and consistent water flow without loss or contamination.Q: How does using the Central Link System benefit long-term operations?

A: By utilizing UV stabilized and corrosion-resistant materials, the Central Link System sustains high performance over long periods, even in demanding outdoor or high-pressure environments. This translates to lowered maintenance needs, fewer replacements, and dependable system longevity for all users.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'RBE Dyeing Machine Controller' category

We export in USA Indonesia, Vietnam, Bangladesh, Ethiopia, Uzbekistan, Sri Lanka, Philippines, Turkey and Mexico.

|

R. B ELECTRONIC & ENGINEERING PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Call Me Free

Call Me Free

Call Me Free

Call Me Free